Rotary tube cutting is an efficient and precise method for cutting tubes in a variety of industries. Whether you are dealing with metal, plastic, or other materials, this technique offers improved productivity and accuracy for your production line. If you’re looking to enhance your cutting processes, rotary tube cutting might be the perfect solution.

In this blog, we’ll explore what rotary tube cutting is, how it works, and how it can benefit your production process.

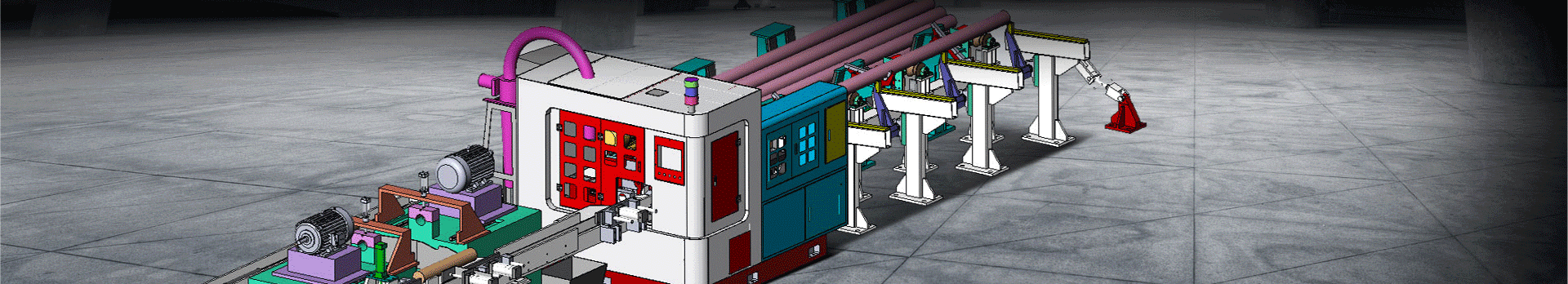

Rotary tube cutting is a method where a rotating cutting tool slices through a tube or pipe in a circular motion. This process is highly versatile, enabling it to cut tubes of various materials like metal, plastic, and composite materials. The main advantage of rotary tube cutting is its speed and precision, making it a preferred choice in industries requiring high-volume, accurate tube cutting.

Unlike traditional cutting methods, rotary tube cutting machines use a rotary motion to make a clean, precise cut without creating excessive heat, reducing the risk of material deformation. These machines are also designed to handle various tube sizes and types, ensuring flexibility and reliability for different production needs.

In rotary tube cutting, a tube is placed on a rotating spindle or clamp, and a rotating cutting tool is applied to the tube’s surface. The cutting tool moves in a circular motion, gradually slicing through the tube to create a clean cut. Depending on the design of the cutting machine, the tube may rotate while the tool remains stationary, or the tool may rotate while the tube stays in place.

The cutting process can be automated for high efficiency and precision, reducing human error and increasing the throughput of your production line. Many rotary tube cutting machines come equipped with programmable controls, allowing for quick adjustments to tube sizes and cutting speeds.

Rotary tube cutting machines deliver precise, smooth cuts with minimal burrs, ensuring that your tubes are cut to exact specifications. This precision is essential for industries where accuracy and high-quality cuts are critical.

The rotary motion allows for faster cutting speeds compared to traditional cutting methods. This leads to higher throughput and reduced downtime, which is essential for businesses that rely on high-volume production.

Because rotary tube cutting produces clean cuts with minimal material loss, it helps reduce waste. This not only saves on material costs but also improves the overall efficiency of your production process.

Rotary tube cutting machines can handle a wide range of tube materials and sizes, making them suitable for various industries, including aerospace, automotive, and construction. Whether you’re cutting small, delicate tubes or large, heavy pipes, rotary cutting offers the flexibility to meet your needs.

Unlike other cutting methods, rotary tube cutting generates very little heat. This reduces the risk of material deformation or warping, ensuring that your tubes retain their integrity and quality after cutting.

Rotary tube cutting is widely used in the aerospace industry for cutting high-precision tubes used in aircraft systems. The ability to make clean, accurate cuts is crucial for ensuring the safety and performance of these components.

In automotive production, rotary tube cutting is used to process tubes for exhaust systems, frames, and other components. The high-speed and precision of the process make it ideal for producing parts quickly and accurately.

Rotary tube cutting is also used in the construction industry to cut pipes and tubes used in plumbing and structural applications. The versatility of rotary cutting machines allows them to handle a wide variety of tube materials, from copper to steel.

The medical industry relies on rotary tube cutting for cutting medical tubes and components used in devices such as catheters, IV lines, and other equipment that require high-precision cuts.

When selecting a rotary tube cutting machine, consider the following factors:

At Keensaw, we offer a range of rotary tube cutting machines that cater to various industrial needs. Our machines are designed to provide high-speed, precise cuts with minimal material waste, helping you improve your production process.

Q: What materials can be cut with rotary tube cutting machines?

Rotary tube cutting machines can cut a variety of materials, including metals (steel, aluminum, copper), plastics, and composites.

Q: How fast can a rotary tube cutting machine cut?

The cutting speed depends on the machine and material, but rotary tube cutting machines are generally faster than traditional methods, offering high throughput.

Q: Does rotary tube cutting cause any material deformation?

No, rotary tube cutting generates minimal heat, which reduces the risk of material deformation or warping.

Q: Can rotary tube cutting machines be automated?

Yes, many rotary tube cutting machines are designed with programmable controls for automation, improving precision and efficiency.

Q: How do I maintain a rotary tube cutting machine?

Regular maintenance involves cleaning, lubricating, and checking the cutting tool’s condition. Be sure to follow the manufacturer’s maintenance guidelines for optimal performance.

Rotary tube cutting is a highly efficient and precise cutting method that can greatly benefit your production line. Whether you’re in the aerospace, automotive, construction, or medical industry, rotary tube cutting offers enhanced precision, increased productivity, and reduced material waste.

Choose Keensaw for your rotary tube cutting needs and experience high-quality, high-performance cutting solutions that boost your production process.

Contact us if you have any questions we will reply as soon aspossible