In modern manufacturing, achieving perfect edges and high-quality finishes is no longer optional—it’s expected. CNC Chamfering Machines have emerged as a game-changer, offering unmatched precision and efficiency in production processes. If you are sourcing equipment, understanding how these machines enhance productivity, reduce waste, and guarantee consistent results will help you make smarter investment decisions.

When you handle precision components, even minor deviations can affect assembly, performance, and aesthetics. CNC Chamfering Machines deliver consistent chamfers, bevels, and edge finishes that manual processes often struggle to replicate.

In a recent case study, a manufacturer upgraded from a semi-automatic chamfering system to a CNC solution. The result was a dramatic reduction in defects and a noticeable improvement in fit for intricate metal frames.

Key Benefits You’ll Notice

Fewer human errors in repetitive tasks

When you invest in a CNC chamfering solution, precision becomes a reliable, repeatable outcome rather than a hopeful expectation.

Time is money, and in fast-paced production, every second counts. CNC chamfering solutions accelerate processes without sacrificing quality. You can handle multiple parts simultaneously or switch between sizes with minimal setup.

One factory reported a 40% increase in throughput after installing a CNC chamfering machine, especially on aluminum and steel parts, which were previously bottlenecks.

Efficiency Advantages

By streamlining your chamfering workflow, efficiency directly translates to higher output and reduced operational costs.

Whether you work with aluminum, stainless steel, or titanium, modern CNC Chamfering Machines adapt quickly. This versatility is crucial if your production mix changes or if you handle custom orders.

A supplier once needed precise chamfers on varying tube diameters from 20mm to 120mm. Switching to a CNC solution allowed them to program multiple profiles without reconfiguring the machine manually.

Versatility You’ll Appreciate

For a procurement perspective, this adaptability ensures your investment remains relevant even as your product line evolves.

Every defective part is lost material and lost time. CNC chamfering reduces scrap by creating precise, repeatable chamfers the first time. Post-processing efforts like manual grinding or filing become nearly unnecessary.

One furniture manufacturer cut down on post-machining polishing by over 60% after adopting a CNC chamfering line, significantly improving both material yield and employee focus on higher-value tasks.

Waste Reduction Highlights

Investing in CNC technology lets you focus on production planning rather than constant quality fixes.

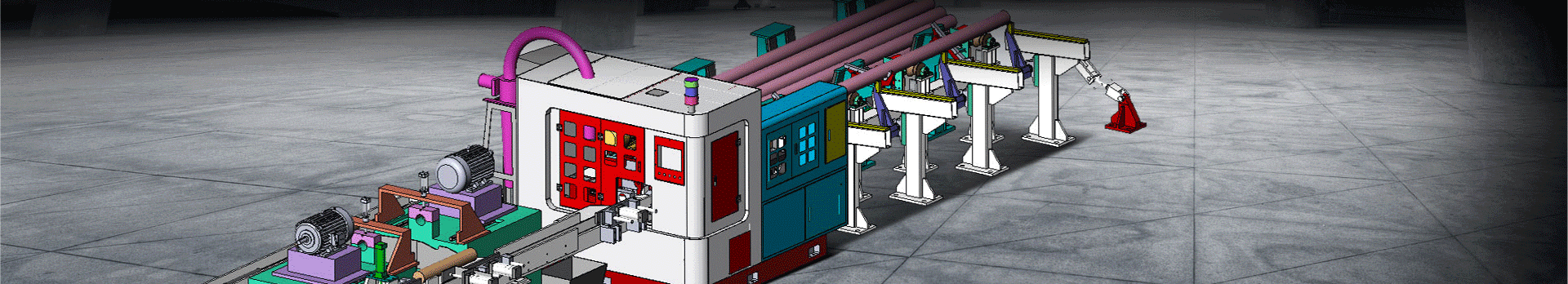

CNC chamfering machines aren’t just standalone tools—they integrate seamlessly into automated production lines. Many models offer programmable interfaces, data tracking, and remote monitoring.

A tubing manufacturer connected their CNC chamfering unit with a robotic feeding system. The result? Fully automated chamfering of hundreds of tubes per shift without operator intervention, while maintaining tight tolerances.

Integration Benefits

For buyers, a machine that fits into your smart factory ecosystem multiplies the return on investment.

When you consider investing in CNC equipment, the brand and support system matter just as much as the machine itself. Keensaw has a long history of designing and manufacturing CNC chamfering machines that deliver consistent results in demanding environments.

Advantages of Choosing Keensaw

Choosing Keensaw ensures you’re not just buying a machine—you’re securing a reliable partner for your manufacturing success.

What makes CNC Chamfering Machines better than manual or semi-automatic systems?

They provide consistent precision, reduce human error, and significantly improve production efficiency.

Can these machines handle different metals and tube sizes?

Yes. Modern CNC machines are versatile, handling a range of diameters and materials with programmable profiles.

How do CNC machines reduce waste?

They produce repeatable chamfers on the first pass, minimizing defective parts and reducing post-processing needs.

Are these machines suitable for both prototypes and mass production?

Absolutely. They can be programmed for one-off custom parts or high-volume production runs.

Is integration with other production equipment possible?

Yes. CNC chamfering machines often support robotic feeders, automated lines, and smart factory data systems.

CNC Chamfering Machines represent the future of manufacturing where precision and efficiency are no longer trade-offs. By adopting these solutions, you reduce waste, accelerate production, and ensure consistent quality across your parts.

As a buyer, investing in a CNC chamfering solution from Keensaw ensures you stay ahead in competitive markets, ready to handle complex designs and diverse production needs with minimal effort. Precision, speed, and versatility are now achievable together—your factory deserves nothing less.

Contact us if you have any questions we will reply as soon aspossible